The Intricacies and Significance of Diecasting in Modern Manufacturing

The Intricacies and Significance of Diecasting in Modern Manufacturing

Blog Article

Diecasting is a specialized manufacturing technique that converts molten metal into precisely defined components using high-pressure molds. This technique has become indispensable in a variety of industries, such as automotive, aerospace, electronics and other consumer goods because it can create complex forms with incredible quality and precision. Combining the fundamentals of metallic engineering with cutting-edge technology, diecasting offers unmatched accuracy and precision, which makes it an integral part of modern manufacturing. This article explores the complicated world of diecasting, exploring its process, advantages and potential applications.

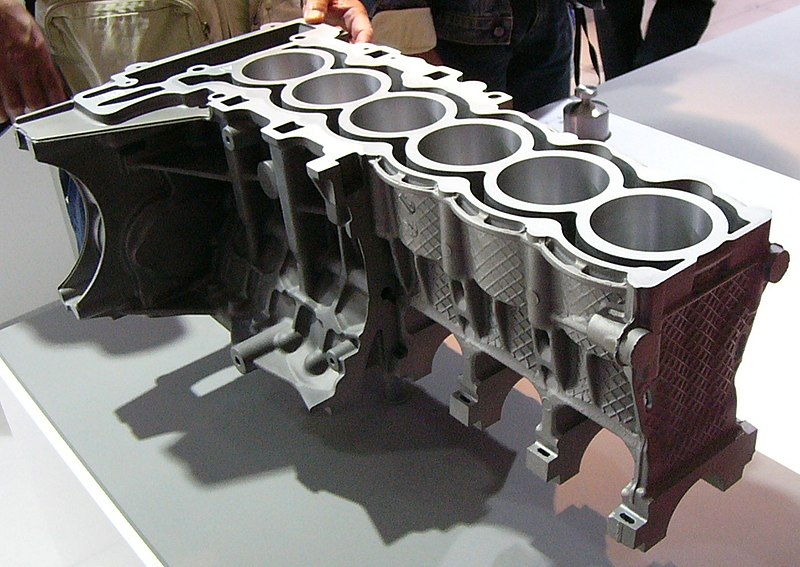

In the heart of diecasting is the use of molds, also known as dies. These are constructed out of high-quality stainless steel, which can stand any harsh elements of the casting process. Die designs are made precisely, usually incorporating precise details and precision tolerances in order to guarantee precision of the final product. The process of diecasting involves the molten metal, which is typically aluminum, zinc or magnesium-is introduced into dies with very high pressure. This rapid injection and solidification result in components with high dimensional stability and flawless surface finish. This reduces the requirement for additional machining or finishing. Precision of the dies permits the creation of complex geometries that would be challenging or impossible to attain using conventional manufacturing processes.

One of the major advantages of diecasting is the capacity to make parts with amazing dimensional precision as well as smooth surface finishes. This is because high-pressure injection makes sure that every detail in the mold is recreated making parts which meet the strictest tolerances and need minimal or no post-production work. This level of precision is particularly beneficial when creating intricate geometries or specific details that may be difficult or impossible to achieve in other manufacturing methods. Furthermore, the ability to repeat diecasting is ideal for large-scale production, ensuring uniformity across a large number of parts. Its effectiveness is also a major source of reductions in costs, since it reduces both material waste and costs for labor.

Diecasting is also a great option regarding the mechanical properties and performance. Parts produced through diecasting are recognized as durable and strong and dependability, both of which are vital properties for components that are utilized for demanding tasks. The fine-grain structure that forms in the process of rapid cooling the metal helps to create these excellent properties, which make diecast pieces suitable for use in highly stressed environments. Moreover, diecasting allows for the incorporation of thin walls and complicated features without compromising the integrity of the finished product. This capability is particularly advantageous in aerospace and automotive industries, where weight reduction whilst maintaining strength and structural integrity is essential to improve energy efficiency and overall efficiency. To acquire additional information please go to Senadiecasting

Diecasting's versatility extends into a variety of applications. In the automotive industry Diecast parts are utilized in transmissions, engines, and structural parts, contributing to more efficient and lighter automobiles. In the field of electronics, diecasting can be used to create heat sinks, housings, as well as connectors that ensure the best thermal management and durability. Home appliances, power tools, and toys also benefit from the precision and effectiveness of diecasting as it produces components that range in size from knobs, handles, and handles to internal mechanisms. The process's adaptability to various metals as well as its capability to create parts that have intricate patterns make it suitable to a variety of industries, all benefiting from unique benefits diecasting provides.

Diecasting is an innovative manufacturing process that combines the highest level of precision, efficacy, and versatility. The ability of diecasting to create complex, high-quality components with superior mechanical properties makes it vital in numerous sectors. The efficiency of diecasting when it comes to mass production, with the material and cost advantages, proves its worth for modern manufacturing. In the future, as industries demand high-performance and reliable components, diecasting will remain a key technology driving innovation and enabling the production of products with advanced technology that satisfy the constantly changing demands of the market. Through its continued growth and development diecasting illustrates the interplay of manufacturing excellence and engineering expertise.